Biodegradable BOPP Film

PAS 9017 certified biodegradable polypropylene film using Polymateria biotransformation technology. Fully biodegrades in the natural environment without creating microplastics. Same performance as standard BOPP, still fully recyclable.

Key Features & Benefits

PAS 9017 Certified

British Standard certification for biodegradation in open-air terrestrial environments - the first standard of its kind

No Microplastics

Fully biodegrades to CO2, water, and biomass - not fragmentation like oxo-degradable films

Same Performance

Identical clarity, stiffness, barrier properties, and machinability to standard BOPP

Still Recyclable

Fully compatible with existing PP recycling streams - gives recycling every chance to happen

Time-Controlled

Remains stable during shelf life (6-24 months), only biodegrades after escaping into the environment

Food Safe

FDA and EU 10/2011 food contact compliant, OECD eco-toxicity tested

About Biodegradable BOPP

For Packaging That Might Escape

Around 22% of plastic waste escapes waste management systems globally. Polyolefins like PP and PE make up over half of all plastic pollution. This biodegradable BOPP addresses what happens when packaging doesn't make it to recycling - it fully biodegrades in the natural environment without leaving microplastics behind.

The Plastic Pollution Problem

Every year, around 350 million tonnes of plastic waste is produced globally. Of this, roughly 22% escapes waste management systems entirely - ending up in uncontrolled dumpsites, burned in open pits, or leaking into terrestrial and aquatic environments. The World Economic Forum estimates that 32% of single-use packaging escapes collection systems.

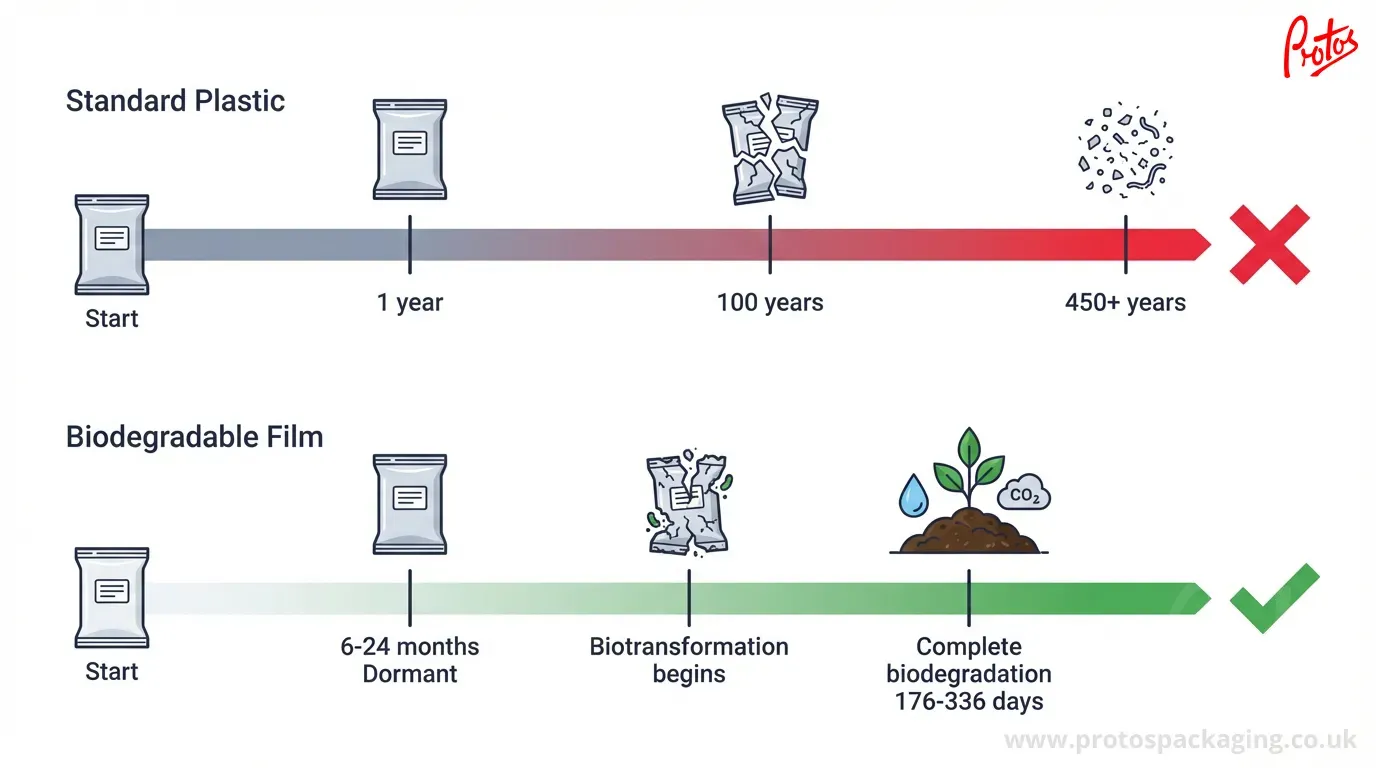

Polyolefins - polyethylene (PE) and polypropylene (PP) - are responsible for over half of all plastic pollution. These materials dominate packaging because they’re cheap, versatile, and perform well. But when they escape into the environment, they persist for centuries, gradually fragmenting into microplastics that contaminate soil, water, and food chains.

Standard recycling doesn’t solve this problem. Even countries with advanced waste management systems leak plastic into the environment. The UK, US, and Europe collectively leak around 170,000 tonnes of plastic into oceans annually, despite having sophisticated collection infrastructure.

What Biodegradable BOPP Offers

Biodegradable BOPP addresses the “fugitive plastic” problem - packaging that escapes collection and ends up in the natural environment. It uses biotransformation technology developed by Polymateria, a British company founded at Imperial College London. The technology is incorporated as a masterbatch additive during film extrusion.

The film performs identically to standard BOPP during its useful life. Same clarity, same stiffness, same barrier properties, same machinability on packaging equipment. The difference only matters if the packaging escapes into the environment - where it will fully biodegrade rather than persisting for centuries.

Critically, the film remains fully recyclable. If it enters the recycling stream, it gets recycled normally. Biotransformation is a failsafe for packaging that doesn’t make it to recycling, not a replacement for recycling.

How Biotransformation Works

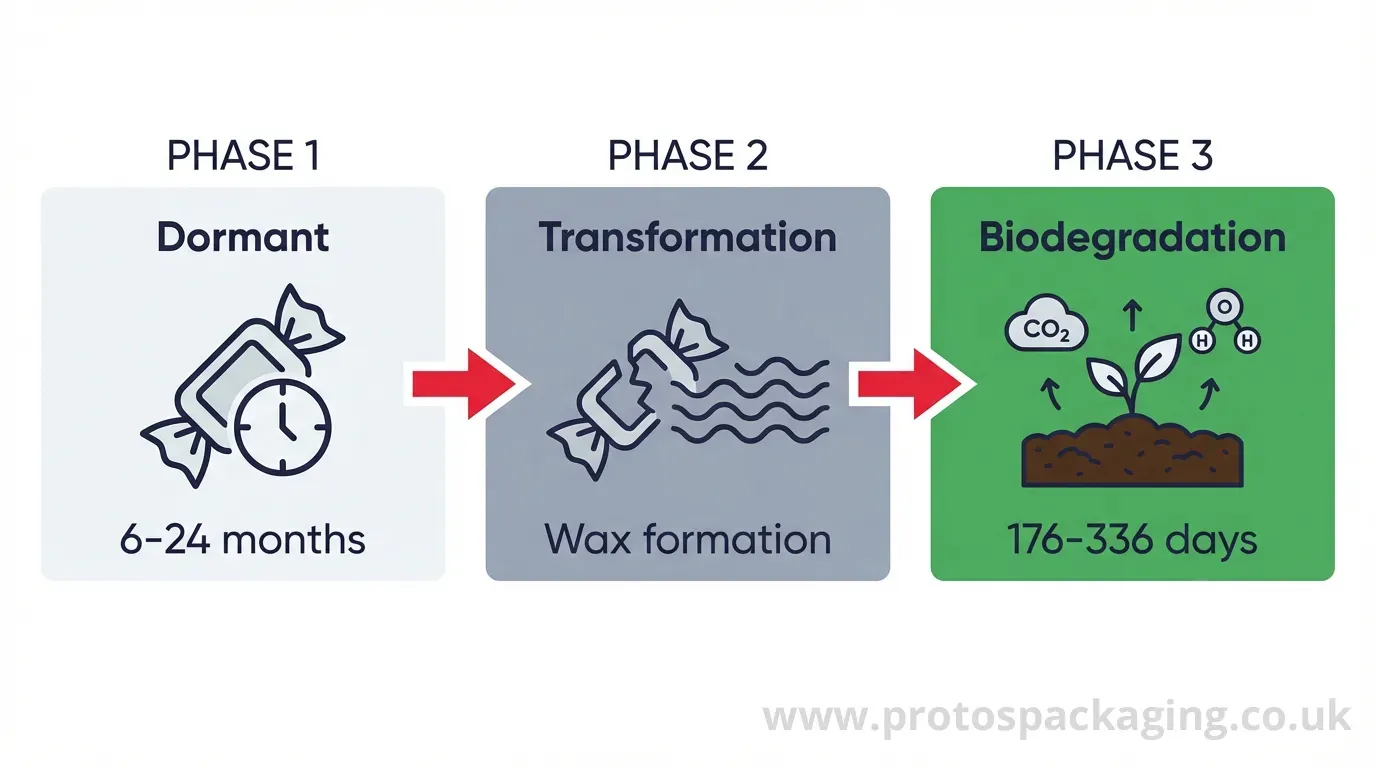

The technology operates in three distinct phases:

Phase 1: Dormant Service Life

During normal use, the masterbatch additives remain completely dormant. The packaging functions exactly like standard BOPP - same shelf life, same product protection, same appearance. The dormancy period is set during manufacturing, typically 6-24 months depending on the application.

This dormancy is critical. It ensures the packaging works properly throughout its intended life, gives recycling every opportunity to happen, and only activates if the material escapes into an unmanaged environment.

Phase 2: Chemical Transformation

Once the dormancy period ends and the material is exposed to environmental conditions (UV light, heat, moisture, oxygen), catalysts in the masterbatch activate. These catalysts attack both the crystalline and amorphous regions of the polymer structure.

The key mechanism is carbon-carbon bond scission - breaking the long polymer chains into much shorter segments. The result is transformation into a wax-like substance with specific characteristics:

- Carbonyl Index greater than 1 (indicating oxidation)

- Loss of more than 90% of molecular weight

- Molecular number weight below 5,000 Daltons

- Ultra-low molecular weight chains that microorganisms can absorb

This wax is no longer a plastic. It’s a bioavailable material that naturally occurring organisms can digest.

Phase 3: Biodegradation

Proprietary ‘synthetic prebiotics’ in the formulation attract natural agents of decay - bacteria, fungi, and other microorganisms found in soil environments worldwide. These organisms colonise the wax and consume it through mineralisation.

The end products are carbon dioxide, water, and biomass - the same outputs as natural organic matter decomposition. No microplastics remain. No harmful residues. The material has fully returned to nature.

Independent laboratory testing (performed to ISO 17556 and ASTM D5988 standards) shows complete biodegradation in 176-336 days under natural terrestrial conditions. The fastest verified result - 176 days for BOPP film - was achieved in partnership with Toppan Specialty Films and verified by the AIMPLAS laboratory in Spain.

PAS 9017: The Certification Standard

PAS 9017:2020 is a British Standard published by BSI Group, developed with input from WRAP, DEFRA, and the Department for Business, Energy and Industrial Strategy. It’s the first standard specifically designed to certify biodegradation of polyolefins in open-air terrestrial environments.

The standard requires three stages of testing:

Stage 1: Weathering and Chemical Transformation

Test materials undergo accelerated weathering (UV exposure per ASTM D4329/ISO 4892-3 or xenon-arc per ASTM D2565/ISO 4892-2). Chemical analysis must demonstrate transformation into wax meeting specific criteria - carbonyl index, molecular weight reduction, and chain length specifications.

Stage 2: Eco-toxicity Assessment

The resulting wax must show no hazardous effects when tested against sentinel species. Required testing includes:

- OECD 207 and 222: Acute and chronic effects on earthworms

- OECD 208: Effects on plants

- OECD 202 and 211: Freshwater acute and chronic toxicity (Daphnia)

This ensures the breakdown products are genuinely safe for ecosystems, not just broken down.

Stage 3: Soil Biodegradation

The material must achieve greater than 90% mineralisation under mesophilic soil conditions, tested per ASTM D5988 or ISO 17556. This is the internationally accepted threshold for biodegradation claims.

Polymateria’s technology was the first to achieve PAS 9017 certification.

What This Is NOT: The Oxo-Degradable Distinction

It’s essential to understand what biodegradable BOPP is not. The EU banned oxo-degradable plastics in July 2021 under the Single-Use Plastics Directive, and for good reason.

Oxo-degradable plastics use pro-oxidant additives that cause plastic to fragment when exposed to heat, light, or oxygen. But fragmentation is not biodegradation. These plastics break into smaller and smaller pieces - ultimately microplastics - that persist in the environment indefinitely. Scientific studies found biodegradation of oxo-degradable plastics is “low to non-existent” in open environments, landfill, and oceans.

Biotransformation is fundamentally different:

| Oxo-degradable | Biotransformation | |

|---|---|---|

| Outcome | Fragments into microplastics | Full biodegradation, no microplastics |

| Mechanism | Chemical decomposition only | Biological consumption by microorganisms |

| Recyclability | Not compatible | Fully recyclable |

| Eco-toxicity testing | Not required | OECD testing mandatory |

| Regulatory status | Banned in EU since 2021 | PAS 9017 certified |

The EU definition of oxo-degradable plastics specifically describes “fragmentation to microplastics or chemical decomposition.” Biotransformation results in biological decomposition to CO2, water, and biomass - a fundamentally different outcome that falls outside the EU ban.

Recyclability

A common concern with biodegradable materials is their impact on recycling streams. PLA and other bioplastics can contaminate conventional recycling if mixed in.

Biodegradable BOPP doesn’t have this problem. Testing against recyclability protocols shows no adverse impact on recycling when mixed into standard PP recycling streams - the mechanical characteristics and optical properties of recycled products remain unaffected at concentrations up to 50%.

The technology is designed to support the waste hierarchy: reduce, reuse, recycle. Biodegradation is the failsafe for the portion of packaging that escapes this hierarchy, not a replacement for it.

Applications

Biodegradable BOPP makes most sense for packaging with high leakage rates - products likely to become litter or escape collection systems:

- Confectionery wrappers - small, light, often discarded away from home

- Snack packaging - consumed on-the-go, high litter rates

- Fresh produce packaging - often removed and discarded in fields

- Bakery bags - frequently escape domestic recycling

- Flower sleeves - discarded with organic waste

- Agricultural films - used in fields where collection is impractical

It’s also relevant for brands with strong sustainability commitments who want packaging that demonstrates a credible end-of-life story backed by third-party certification rather than vague claims.

Limitations and Honest Caveats

Won’t biodegrade in landfill. Landfills are designed to be stable, anaerobic environments where nothing degrades. This technology is specifically for fugitive plastic in open terrestrial environments, not managed waste.

Won’t biodegrade in the ocean. PAS 9017 covers terrestrial environments only. While most ocean plastic originates from land (carried by rivers from unmanaged waste), the testing and certification specifically covers soil biodegradation.

RecyClass position. RecyClass, the European recyclability certification body, has stated that degradable plastics are “explicitly excluded from the scope” of their recyclability protocols because they’re designed for conventional recycling streams. Testing was conducted by Impact Solutions following RecyClass methodology, but RecyClass itself hasn’t endorsed the results. This is an ongoing area of industry discussion.

Cost premium. Expect approximately 30% higher cost compared to standard BOPP, plus around 2% additional loading weight. For many applications this is justified by the sustainability benefits; for others it may not be.

Not a silver bullet. Biodegradable packaging doesn’t solve overconsumption, doesn’t make littering acceptable, and doesn’t replace the need for better waste management infrastructure. It’s a pragmatic solution for the reality that some packaging will always escape collection.

The Business Case

For brands evaluating biodegradable BOPP, the value proposition is:

Genuine sustainability credentials. PAS 9017 is a rigorous, third-party standard developed with government input. It provides defensible claims against greenwashing accusations.

No performance compromise. Unlike some eco-alternatives that require equipment modifications or accept reduced barrier properties, biodegradable BOPP performs identically to conventional film.

Supply chain simplicity. Drop-in replacement with no changes to existing converting, printing, or packaging equipment.

Risk mitigation. As extended producer responsibility schemes expand and plastic taxes increase, having a certified biodegradable option in your portfolio provides flexibility.

Consumer expectations. Public concern about plastic pollution continues to grow. Packaging that demonstrably addresses end-of-life concerns has marketing value.

Technical Comparison

| Standard BOPP | Biodegradable BOPP | |

|---|---|---|

| Film performance | Excellent clarity, stiffness, machinability | Equivalent |

| Shelf life | 12-24 months | 6-24 months (configurable) |

| Recyclability | Yes (EU 10/2011) | Yes (EU 10/2011, FDA) |

| End of life | Persists, fragments to microplastics | Biodegrades in 176-336 days, no microplastics |

| Cost | Baseline | +30% approximately |

Working With Protos

We convert biodegradable BOPP into the same product formats as our standard range - bags, pouches, reels, and sheets. The material should run on your existing packaging equipment with no modifications required - same sealing temperatures, same line speeds.

If you’re exploring biodegradable options, we’re happy to provide trial quantities so you can test it on your lines before committing to a full order. For ongoing requirements, our stockholding service lets you secure pricing and availability while calling off smaller quantities as needed.

Technical specifications and material properties.

Biodegradation Standard

PAS 9017:2020

Biodegradation Time

176-336 days in natural environment

Thickness Range

20μm to 50μm

Clarity

Equivalent to standard BOPP

Recyclability

Fully recyclable with PP streams

Food Grade

EU 10/2011 and FDA Compliant

Eco-toxicity

OECD 202, 207, 208, 211, 222 compliant

Cost Impact

Approximately 30% premium over standard BOPP

This material is commonly used in the following industries:

Confectionery

UK supplier of flexible packaging films for chocolate, sweets, and confectionery. Flow wrap, twist w...

Bakery

UK manufacturer of bakery packaging. Perforated bread bags, centre-folded film for L sealers, BOPP f...

Fresh Produce

UK manufacturer of flexible packaging films for fresh produce. Perforated films for salads, soft fru...

Commercial Director

Speciality Tea Company

Interested in Biodegradable BOPP?

If you're looking for packaging that performs like standard BOPP but has a genuine end-of-life solution for fugitive plastic, let's talk.