PLA Compostable Film

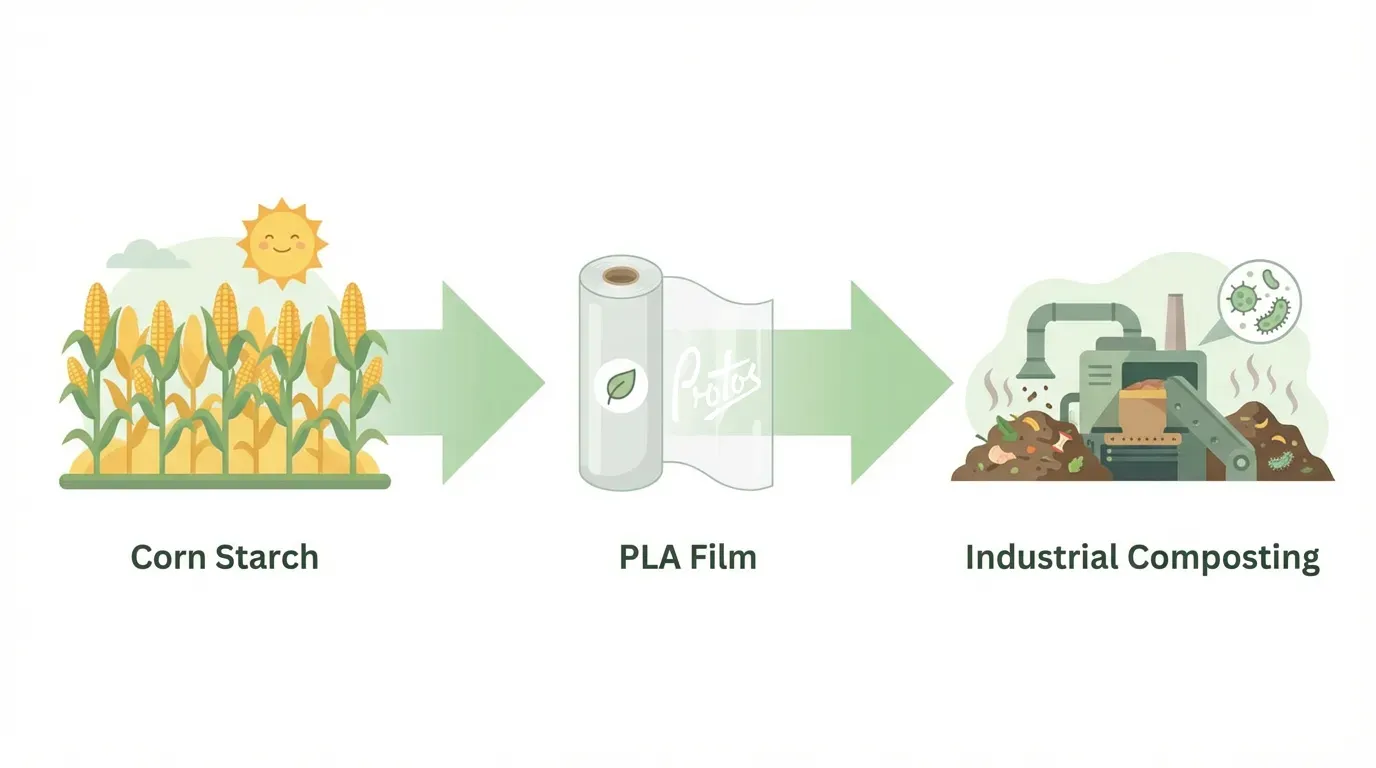

PLA (polylactic acid) film from renewable corn starch or sugarcane. Industrially compostable to EN 13432, bio-based alternative to conventional plastics. Converted in the UK into reels, bags, and sheets for food packaging.

Key Features & Benefits

Bio-Based Material

Made from renewable corn starch or sugarcane - not petroleum. Reduces reliance on fossil fuels

Industrially Compostable

EN 13432 certified - breaks down in commercial composting facilities within 90 days

Excellent Clarity

Crystal clear with high gloss - comparable optical properties to PET for product visibility

Food Safe

FDA GRAS and EU approved for direct food contact across all food types

Runs on Standard Equipment

Compatible with existing flow wrap, shrink wrap, and form-fill-seal machinery

Printable Surface

Good ink adhesion for flexographic and gravure printing - accepts branding and graphics

About PLA Film

The Bio-Based Plastic Alternative

PLA (polylactic acid) is a bio-based plastic made from fermented plant starch - typically corn or sugarcane. It offers a renewable alternative to petroleum-based plastics for brands seeking to reduce their fossil fuel dependency. The material is industrially compostable and provides excellent clarity comparable to PET.

What is PLA?

PLA (polylactic acid) is a thermoplastic made from fermented plant starch - predominantly corn, though sugarcane and other feedstocks are also used. Unlike conventional plastics derived from petroleum, PLA comes from annually renewable agricultural sources.

The production process converts plant sugars into lactic acid through fermentation, then polymerises this into polylactic acid. The result looks, feels, and handles much like conventional plastic film, with excellent clarity and gloss that makes it suitable for applications where product visibility matters.

PLA is the most widely produced bioplastic globally, appealing to brands wanting to reduce fossil fuel dependency and communicate environmental credentials to consumers.

Why Brands Choose PLA

PLA is made from plants, not petroleum. This “made from corn” story resonates with consumers and reduces reliance on fossil fuels. The carbon absorbed by crops during growth partially offsets emissions from production.

The material offers excellent clarity and gloss - optical properties comparable to PET - making it suitable for applications where product visibility matters. It’s FDA GRAS approved and EU compliant for food contact across all food types.

PLA is certified compostable to EN 13432 and ASTM D6400. In commercial composting facilities operating at 58°C, it breaks down within 45-90 days into CO2, water, and biomass. It also runs on conventional packaging machinery - flow wrap, shrink wrap, form-fill-seal - with parameter adjustments for its lower heat tolerance.

Important Considerations

We believe in honest advice. PLA has genuine benefits, but also limitations you should understand:

Industrial Composting Only

PLA requires sustained temperatures of 58°C and the presence of specific microorganisms to break down. These conditions exist in industrial composting facilities but not in home compost bins. Outside industrial composting, PLA behaves much like conventional plastic - it won’t decompose in landfill, won’t break down in the natural environment, and won’t degrade in seawater.

This is important: the “compostable” claim only applies if the packaging actually reaches an industrial composting facility. In the UK, access to such facilities that accept packaging is limited.

Contaminates Recycling Streams

PLA looks similar to PET but has a much lower melting point (around 150-160°C vs 260°C for PET). If PLA gets into PET recycling, it melts at the wrong temperature, causing clogs, degrading quality, and potentially ruining entire batches. Even small amounts of PLA can contaminate recycling loads.

This creates a real problem: consumers may put PLA in recycling bins (thinking they’re being responsible), which actually causes harm. PLA needs separate collection and processing infrastructure that doesn’t widely exist.

Subject to UK Plastic Packaging Tax

Despite being bio-based, PLA is classified as plastic under UK legislation. It attracts the full Plastic Packaging Tax unless it contains 30% recycled content - which is rarely available for PLA since dedicated PLA recycling infrastructure is limited.

Heat Sensitivity

PLA softens at around 60°C (its glass transition temperature). This makes it unsuitable for hot-fill applications, microwavable packaging, or products stored in warm environments. In hot weather, PLA packaging can deform.

More Brittle Than Conventional Films

While PLA is flexible, it’s more brittle than films like BOPP or CPP. It has lower elongation at break, making it more prone to cracking under stress, and it marks and scratches more easily.

Shorter Shelf Life

PLA film degrades faster than conventional plastics - typically 6-12 months from manufacture under ideal storage conditions. This creates supply chain challenges, particularly for exported products or slow-moving stock.

Our Honest View

We supply PLA because some customers specifically need it. But for most applications seeking “sustainable packaging,” we generally recommend alternatives:

NatureFlex is usually the better choice if you need genuine compostability. It’s certified for home composting (not just industrial), exempt from the UK Plastic Packaging Tax, and won’t contaminate recycling streams the same way. The cost is higher, but when you factor in PLA’s tax liability, the gap narrows.

Biodegradable BOPP is often more practical. It offers identical performance to standard BOPP, can be recycled in PP streams, and will biodegrade in the natural environment if it escapes collection (certified to PAS 9017). It doesn’t require industrial composting infrastructure.

We’re not tied to any single material, so our advice is based purely on what works best for your application. If PLA genuinely makes sense for your needs, we’ll supply it. If something else would serve you better, we’ll tell you.

PLA vs NatureFlex

| PLA | NatureFlex | |

|---|---|---|

| Raw material | Corn/sugarcane (polylactic acid) | Wood pulp (cellulose) |

| Home compostable | No | Yes (most grades) |

| Industrial composting | Yes (EN 13432) | Yes (EN 13432) |

| UK Plastic Tax | Taxed | Exempt |

| Recycling impact | Contaminates PET/PP streams | Should not enter plastic recycling |

| Heat resistance | Poor (60°C) | Good |

| Moisture barrier | Moderate | Good (NK grades) |

| Cost | Moderate-high | High |

PLA vs Biodegradable BOPP

| PLA | Biodegradable BOPP | |

|---|---|---|

| Raw material | Corn starch (renewable) | Polypropylene (petroleum) |

| End of life | Industrial composting | Biodegrades in natural environment |

| Certification | EN 13432 (composting) | PAS 9017 (environmental biodegradation) |

| Recyclable | No (contaminates streams) | Yes (PP streams) |

| UK Plastic Tax | Taxed | Taxed (unless 30% recycled) |

| Heat resistance | Poor | Good |

| Performance | Good clarity, moderate barrier | Identical to standard BOPP |

| Weight | Moderate | Light |

When PLA Makes Sense

Despite the caveats, PLA can be appropriate for specific situations:

Closed-Loop Industrial Composting

If your product will be consumed in settings with guaranteed access to industrial composting - stadiums, festivals, corporate campuses with commercial waste streams - PLA packaging can be processed with food waste in a controlled manner.

Brand Positioning Requirements

Some brands specifically want “made from plants” messaging. PLA’s corn-based origin resonates with consumers, even if the practical end-of-life is complex. For marketing purposes, “plant-based” can be more compelling than “biodegradable” to certain audiences.

Shrink Film Applications

PLA shrinks uniformly with less heat than conventional shrink films, making it efficient for shrink wrapping bottles, boxes, and promotional multipacks. The lower shrink temperature can reduce energy consumption compared to PVC shrink.

Window Patching

PLA’s clarity makes it suitable for window patches in cartons where you want to show the product. The film provides excellent product visibility with bio-based credentials.

PLA Film Types

Clear PLA

Crystal clear with high gloss, comparable to PET. Available in thicknesses from 20-75μm. Used for flow wrap, bags, pouches, and window patching.

Anti-Mist PLA

Treated to prevent condensation inside packs. Used for chilled applications where products need to remain visible despite temperature changes.

PLA Shrink Film

Specifically engineered for shrink wrapping. Available in gauges from 80 to 140. Shrinks at lower temperatures than conventional films (typically 80-100°C vs 150°C+ for PVC).

Metallised PLA

PLA with a thin aluminium layer for enhanced barrier and metallic appearance. Used for premium applications and products needing light barrier.

Machine Compatibility

PLA runs on standard packaging equipment:

- Flow wrap (horizontal form-fill-seal) - with temperature adjustments

- Shrink wrap - lower tunnel temperatures than conventional films

- Vertical form-fill-seal - for pouches and sachets

- Window patching - for cartons requiring clear panels

The main consideration is heat management. PLA’s lower softening point means sealing and tunnel temperatures need adjustment from conventional film settings. Most equipment accommodates this with parameter changes.

Composting Requirements

For PLA to compost, it needs:

- Temperature: 58°C sustained

- Moisture: High humidity

- Microorganisms: Active composting environment

- Time: 45-90 days under optimal conditions

These conditions exist in industrial composting facilities. In home compost bins (typically 10-30°C), PLA remains largely intact. In landfill (anaerobic, low temperature), PLA persists indefinitely.

Before specifying PLA, verify that your customers’ waste streams actually reach appropriate composting facilities. Without this infrastructure, PLA’s compostability benefit is theoretical rather than practical.

Storage and Handling

PLA requires careful handling:

- Store at 17-23°C away from heat sources

- Keep humidity below 50%

- Use within 6-12 months of manufacture

- Protect from UV light

- Handle with care - PLA scratches more easily than conventional films

UK Plastic Packaging Tax

PLA is subject to the UK Plastic Packaging Tax because it’s classified as a polymer. This creates a tax disadvantage compared to:

- NatureFlex - exempt (cellulose not classified as plastic)

- Cellophane - exempt (same reason)

- Recycled-content films - exempt if 30%+ recycled content

What We Supply

We convert PLA into multiple formats at our UK facility:

- Reels - for flow wrap, shrink wrap, and automated packaging

- Bags - various styles for retail and foodservice

- Sheets - for manual operations and window patching

Conversion services include slitting, sheeting, bagmaking, and printing.

Printing on PLA

PLA accepts flexographic and gravure printing with appropriate surface treatment. The film’s clarity and gloss provide a good base for vibrant graphics.

Corona treatment ensures ink adhesion. Print quality is comparable to conventional films, though care is needed with drying temperatures to avoid film distortion.

Working With Us

We can supply PLA if you need it - but we’ll also give you an honest assessment of whether it’s the right choice. For many “sustainable packaging” requirements, NatureFlex or biodegradable BOPP may serve you better.

We’re a family business, not tied to any single supplier or material. That means our recommendation is based purely on what works for your application, not what we’re trying to sell. Get in touch to discuss your requirements.

Technical specifications and material properties.

Thickness Range

20μm to 75μm

Maximum Width

1500mm

Composting

Industrial only (EN 13432)

Heat Resistance

Max 60°C

Bio-based Content

100% renewable

Food Grade

FDA GRAS, EU 10/2011

Plastic Tax

Taxed

Recyclability

Not recyclable

This material is commonly used in the following industries:

Need Bio-Based Packaging Film?

If you're exploring PLA for its renewable credentials, we can convert it to your specification. Get in touch to discuss your requirements.