Polymateria DegrAid: The Panacea for Biodegradable Plastic Packaging?

At Protos Packaging, with three decades of industry experience, we’ve explored many eco-friendly packaging options including our ProGanic range - materials made from corn, potato starch, and wood pulp. Today we examine Polymateria DegrAid, a material additive that claims to enable standard BOPP plastic to become fully biodegradable while preserving recyclability and maintaining existing performance characteristics.

What is Polymateria DegrAid?

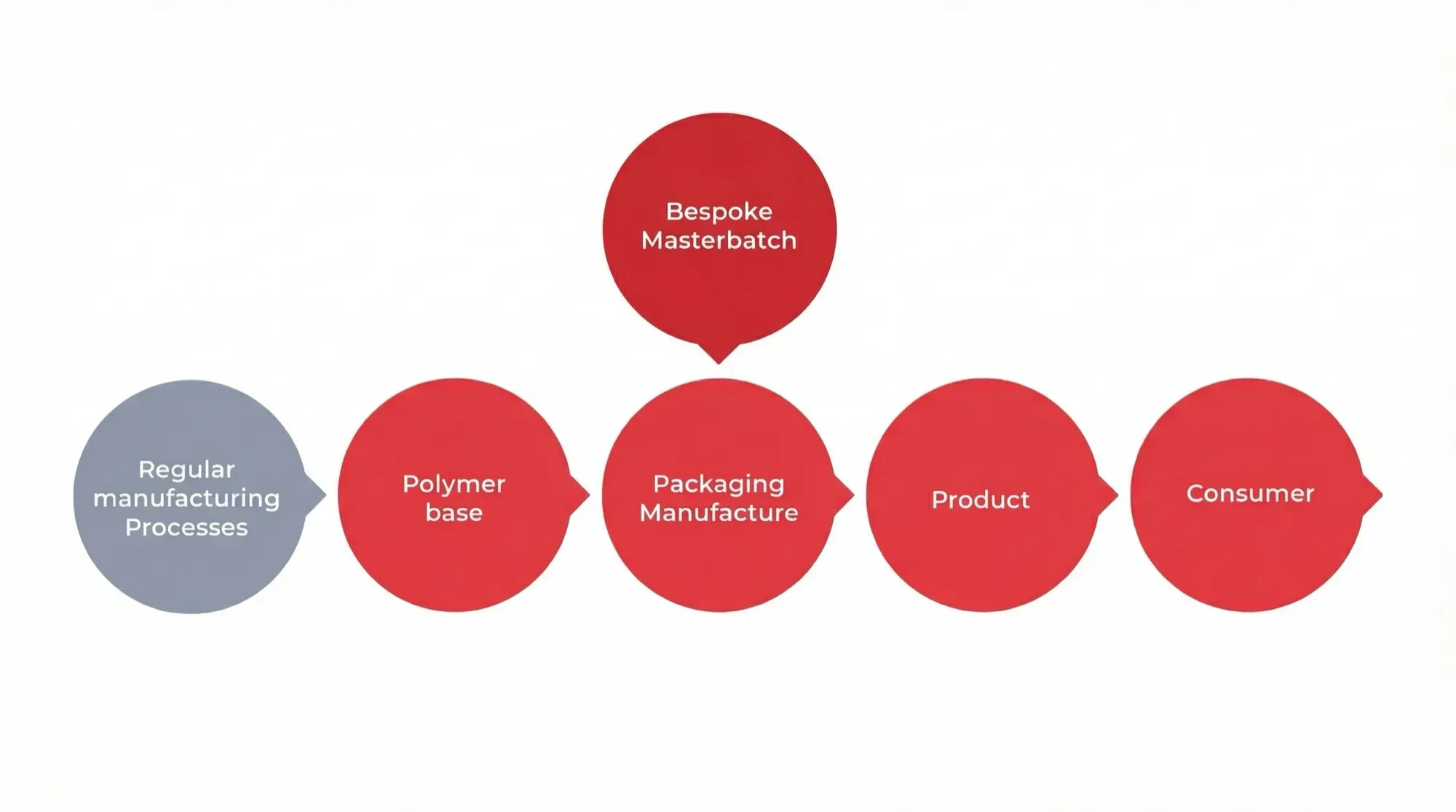

This additive is introduced during the extrusion manufacturing phase, remaining stable until a predetermined timeframe (6-24 months) when it triggers breakdown into harmless wax consumed by environmental microbes. The process produces only carbon dioxide and water, with no microplastic remnants.

The technology requires no supply chain modifications, maintains product performance, and permits circular economy participation. The additive meets FDA and EU food-contact regulations (EU regulation 10/2011) and complies with OECD standards for environmental safety affecting earthworms, plants, and aquatic organisms.

How Does It Compare?

When positioned against alternatives like PLA and NatureFlex, DegrAid offers some distinct advantages:

- Cost: Approximately 30% premium over standard materials (compared to 4-5x for some bioplastics)

- Weight: Minimal increase of around 2%

- Recyclability: Maintains full recyclability within standard waste streams

- Shelf life: Programmable 6-24 months before biodegradation begins

The ability to recycle the material through existing infrastructure, rather than requiring separate composting facilities, addresses one of the key limitations of many bioplastic alternatives.

The Three-Phase Biotransformation Process

The technical mechanism operates as follows:

Phase 1: A masterbatch containing dormant technologies is incorporated during manufacturing without affecting recyclability or product specifications. During this phase, the material behaves exactly like conventional BOPP.

Phase 2: Upon activation following product shelf-life, the material rapidly loses physical properties, converting into bioavailable wax through exposure to crystalline and amorphous polymer regions. This is the transition phase where the plastic ceases to function as packaging.

Phase 3: Natural bacteria and fungi mineralise the wax at ambient temperatures, producing water and biomass, achieving 90% biodegradation within two years. Crucially, no microplastics remain.

Our Assessment

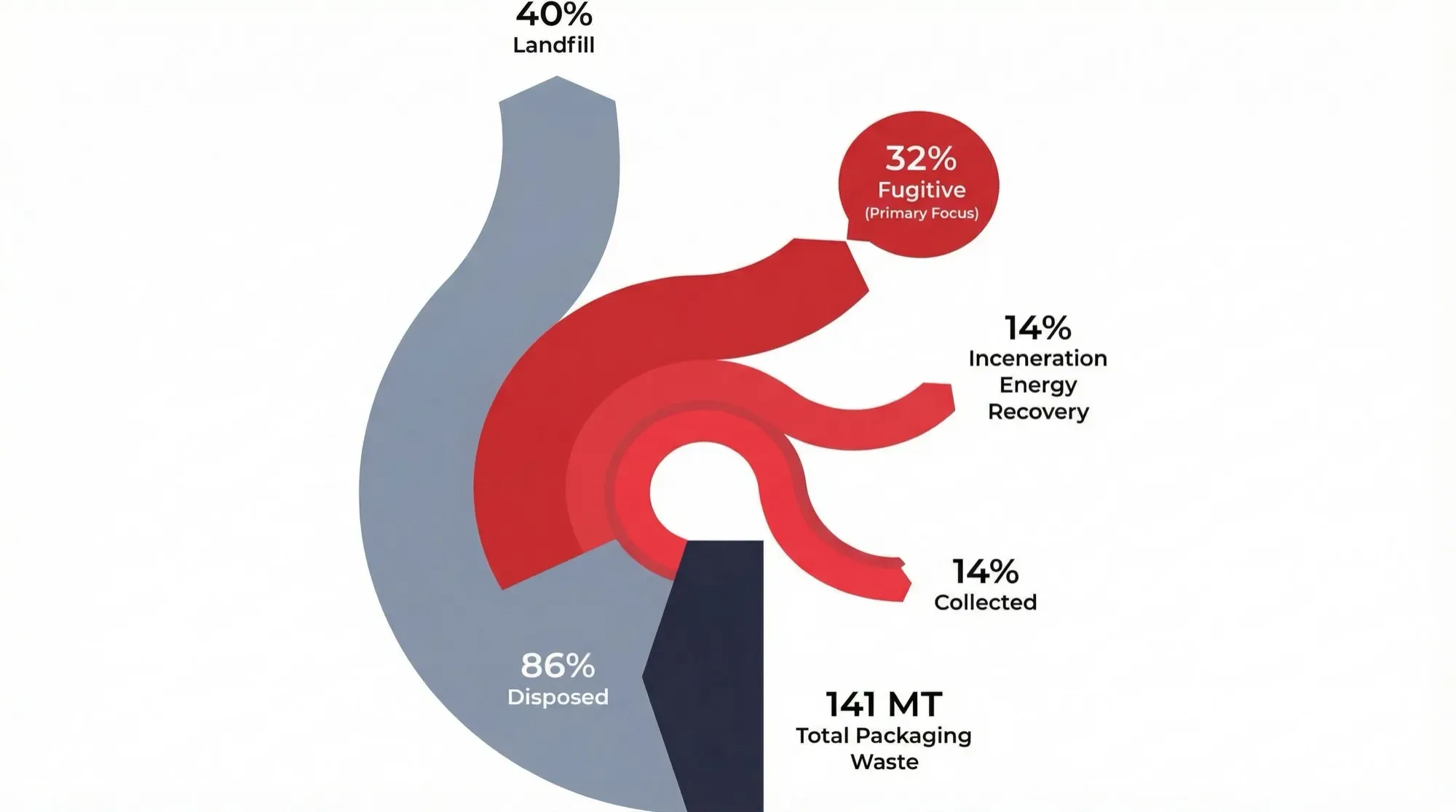

The technology is promising. Unlike the oxo-degradable additives we’ve previously criticised for merely fragmenting plastic into microplastics, DegrAid claims complete biodegradation with no persistent residues.

However, we approach such claims with healthy scepticism born of decades in this industry. The key questions are:

- Does the 90% biodegradation claim hold up under real-world conditions, not just laboratory settings?

- What happens to the remaining 10%?

- How does the technology perform across the full range of environmental conditions found in UK landfill and litter scenarios?

We’ll continue to monitor the development of this technology and others like it. The packaging industry needs genuine solutions to the end-of-life challenge, and innovations like DegrAid deserve serious evaluation - neither dismissed out of hand nor accepted uncritically.

For now, our recommendation remains that the most environmentally sound approach combines material reduction, design for recyclability, and - where genuine biodegradability is required - proven bioplastic materials from renewable sources. But technologies like DegrAid may yet prove to be part of the solution.

Update: We now offer Biodegradable BOPP using Polymateria’s biotransformation technology, certified to PAS 9017.