Laminate Packaging Film

Multi-layer laminate films combining PET, BOPP, PE, nylon, foil and paper for enhanced barrier properties. Printed laminates for food packaging - coffee, snacks, confectionery, pet food. Sandwich printing for scratch-resistant graphics.

Key Features & Benefits

Combined Barrier Properties

Multiple layers work together - oxygen, moisture, light, and aroma barriers in one structure

Sandwich Printing

Print trapped between layers for scratch-resistant, high-gloss graphics that won't scuff

Tailored Performance

Specify the exact combination of properties your product needs - no compromise

Extended Shelf Life

High-barrier structures protect oxygen-sensitive products like coffee and snacks

Heat Resistant Options

Retort and ovenable grades for ready meals and products requiring thermal processing

Recyclable Options

Polyolefin laminates (PE/PP) now OPRL-classified as recyclable via front-of-store collection

About Laminate Films

Combined Properties in One Film

A laminate combines two or more films bonded together to create a structure with properties no single material can achieve alone. Each layer contributes something different - barrier, strength, sealability, appearance - resulting in packaging precisely engineered for your product.

What is a Laminate?

A laminate is a packaging film made from two or more layers bonded together. Each layer contributes different properties - one might provide oxygen barrier, another heat sealability, another printability - creating a structure that outperforms any single material.

In an ideal world, we’d have mono-material films that tick every box: excellent barrier, perfect sealability, great printability, fully recyclable. The reality is that no single film does everything well. BOPP has excellent clarity and stiffness but limited oxygen barrier. Polyester has good barrier but needs a sealant layer. Polyethylene seals beautifully but has poor oxygen barrier. Laminates solve this by combining materials strategically - using each where it performs best.

The layers are typically bonded using adhesives or by co-extrusion where polymers are combined at the molten stage. The result is a unified film that handles as one material but delivers the combined benefits of its components.

Why Use Laminates?

For many applications, mono-films work fine. BOPP handles most bakery and confectionery. CPP suits applications needing flexibility and heat resistance. But when you need barrier properties that mono-films can’t deliver, laminates become essential.

Consider coffee packaging. Standard BOPP has an oxygen transmission rate around 1,000-1,500 cc/m²/day. Add a metallised layer and you’re down to 10-50 cc/m²/day. Add aluminium foil and it’s essentially zero. That’s the difference between coffee going stale in weeks versus staying fresh for months.

Laminates also enable sandwich printing - where the design is printed on the reverse of a clear outer layer, then protected by the lamination. The graphics are trapped between films, completely protected from scuffing, scratching, and abrasion through distribution and retail handling.

Common Laminate Structures

PET/PE (Polyester/Polyethylene) - A workhorse 2-ply structure. PET provides stiffness, clarity, and print surface. PE provides heat sealability and moisture barrier. Used for snack packaging, confectionery, and general food applications where moderate barrier is sufficient.

BOPP/CPP (Polypropylene/Cast Polypropylene) - Another popular 2-ply combination. BOPP gives excellent clarity and stiffness for the outer layer. CPP provides a soft, flexible seal layer with good heat resistance. Common for biscuits, confectionery, and bakery products. This all-polyolefin structure is now classified as recyclable via front-of-store collection under OPRL guidelines.

PET/Metallised PET/PE - A 3-ply structure with a metallised middle layer for enhanced barrier. The thin aluminium coating on the middle PET layer dramatically reduces oxygen and moisture transmission. Used for snacks, coffee, and products needing extended shelf life without full foil barrier.

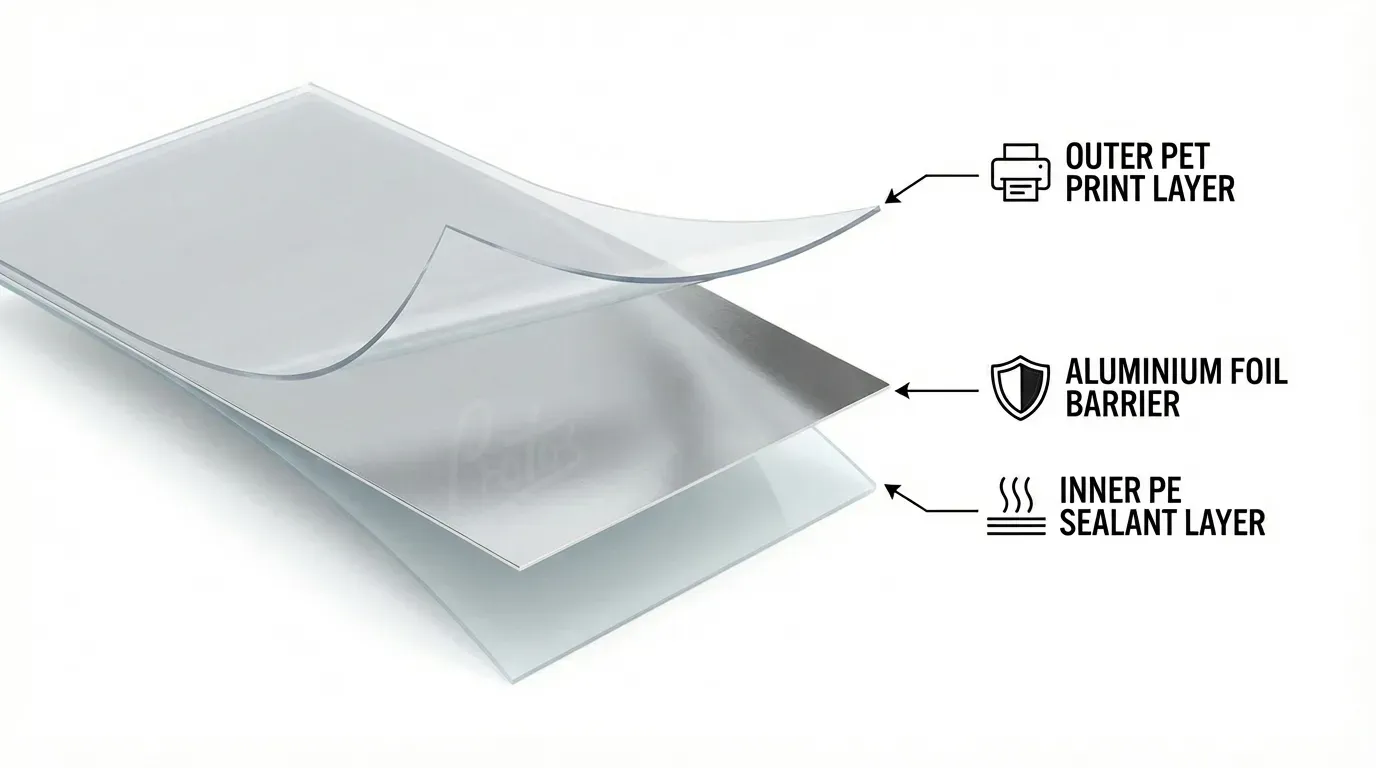

PET/Aluminium Foil/PE - The ultimate barrier structure. Aluminium foil provides near-total barrier to oxygen, moisture, light, and aroma. Essential for coffee and anything requiring maximum protection. The foil is sandwiched between PET (for printability and puncture protection) and PE (for sealability).

PET/Nylon/PE - Nylon (polyamide) adds puncture resistance and oxygen barrier. This structure is common for vacuum packaging, cheese, processed meats, and applications where the pack might be subjected to physical stress during distribution.

Paper/PE or Paper/Metallised Film/PE - Paper outer layers give a natural, tactile feel that appeals to consumers. The plastic layers provide barrier and sealability that paper alone cannot achieve. Popular for premium positioning and brands wanting to communicate sustainability.

Specialist Laminate Types

Retort Laminates are engineered to withstand the temperatures and pressures of retort processing (typically 121°C for 30-60 minutes). Used for ready meals, pet food, and shelf-stable products. Structures typically include PET, nylon, and CPP - materials that maintain integrity at high temperatures.

Ovenable Laminates are designed to go from freezer to oven. The outer layers withstand oven temperatures (typically up to 200-220°C) while the sealant layer releases cleanly for easy opening. Used for ready meals, frozen prepared foods, and cook-in-pack applications.

Lidding Films are laminates designed to seal to trays (APET, CPET, PP). Available with different peel characteristics - easy peel, medium peel, weld seal - depending on the application. Anti-fog coatings available for chilled products where visibility matters.

High Barrier Films use aluminium foil or EVOH (ethylene vinyl alcohol) barrier layers for maximum protection. Essential for oxygen-sensitive products like coffee, nuts, and dried foods requiring extended ambient shelf life.

Applications

Coffee and Tea - High-barrier laminates with foil or metallised layers. Oxygen and moisture barrier critical for flavour preservation. Often includes a degassing valve for freshly roasted coffee. Premium graphics to communicate quality.

Snack Foods - Metallised laminates provide barrier against oxygen and light while delivering a premium metallic appearance. Modified atmosphere packaging (MAP) maintains crispness. Sandwich printing protects graphics through distribution.

Pet Food - Heavy-gauge laminates with nylon for puncture resistance. High barrier to maintain nutritional value and prevent fat oxidation. Large format bags need strength to handle weight without splitting.

Confectionery - From simple BOPP/CPP flow wrap to high-barrier foil laminates for premium chocolates. Appearance is critical - sandwich printing and specialist finishes like matte, soft-touch, or metallised effects.

Ready Meals - Retort or ovenable laminates depending on the process. Lidding films to seal to trays. Anti-fog for chilled products. Easy-peel for consumer convenience.

Protein and Meat - Nylon-containing laminates for puncture resistance and oxygen barrier. Vacuum packaging or MAP. Thermoformable structures for skin-pack applications.

Recyclability

Multi-material laminates have traditionally presented recycling challenges - when different polymers are bonded together, they’re difficult to separate.

However, OPRL guidance now classifies polyolefin laminates (PE and PP combinations) as recyclable via front-of-store collection points. This includes structures like BOPP/CPP and OPP/PE, provided they meet specific criteria: minimum 90% polyolefin content, limited amounts of barrier coatings, and metallisation (if present) applied as a thin vacuum-deposited layer rather than foil.

This is driving development of mono-material laminate alternatives - PE/PE or PP/PP structures that sacrifice some performance for improved recyclability. Barrier properties come from specialist coatings rather than different polymer layers.

For applications requiring full foil barrier (coffee, for example), traditional multi-material laminates remain the practical choice. The product protection requirements outweigh the recyclability limitations. We can advise on the options for your specific application.

What We Supply

We source laminates from UK manufacturing partners and can supply:

- Reels - for flow wrap, VFFS, HFFS, and lidding applications

- Bags - converted from laminate structures

- Sheets - for manual wrapping or specialty applications

We hold stock of common laminate structures and can specify bespoke combinations for specific requirements. Lead times for printed bespoke laminates are typically 6-8 weeks.

Working With Us

Choosing the right laminate structure means balancing barrier requirements, mechanical properties, print quality, sustainability goals, and cost. Sometimes a mono-film like BOPP or a coated film is sufficient. Sometimes you genuinely need a multi-layer laminate.

We’re happy to discuss your application and recommend appropriate options. If you’re currently using an over-specified laminate where something simpler would work, or using a mono-film where a laminate would improve shelf life or presentation - get in touch. We’ll give you honest advice on what’s actually needed for your product.

Technical specifications and material properties.

Thickness Range

50μm to 120μm

Maximum Width

1500mm

Structure Options

2-ply, 3-ply, 4-ply

Barrier Types

Foil, metallised, EVOH, nylon

Printing

Surface or reverse (sandwich)

Food Grade

BRC certified supply chain

Recyclability

Limited (polyolefin only)

This material is commonly used in the following industries:

Coffee & Tea

UK manufacturer and supplier of flexible packaging films for coffee and tea. Flow wrap for ground co...

Confectionery

UK supplier of flexible packaging films for chocolate, sweets, and confectionery. Flow wrap, twist w...

Pet Food

UK manufacturer of flexible packaging films for pet food. Flow wrap for dry food and biscuits, liddi...

Protein & Meat

UK manufacturer of flexible packaging films for meat, poultry, and protein products. Lidding films f...

Need Laminate Packaging Film?

Whether you need a stock laminate or a bespoke structure for a specific application, we can help. Get in touch to discuss your requirements.